|

Application & Process :

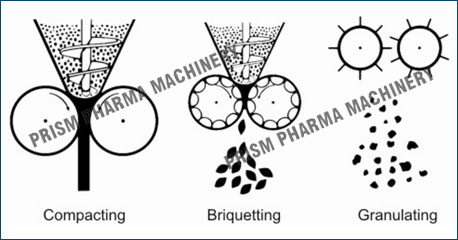

The Roll Compactor machine is used for increased bulk density, making granules, dust free processing and reducing particle size of pharmaceutical ingredients in pharmaceutical industry, in food as well as chemical industry for densification and granulation of powder.

The material in form of powder passes through the two counter rotating rolls of roller compactor under very high pressure. As the volume decreases through the region of maximum pressure, the material is formed into a solid compact sheet or flakes of ingredients. These flakes or compact sheet of ingredients are reduced in size to obtain the desired grain size. The machine takes extra care to prevent the generation of fine during this process.

Free flowing granules for Automatic packing Free flowing granules for Automatic packing

Compact granules to reduce package size Compact granules to reduce package size

Dust Free granules to facilitate handling Dust Free granules to facilitate handling

Granules to fill in smaller capsule Granules to fill in smaller capsule

Granules for Tabletting. Granules for Tabletting.

Salient Features: :

- Design is cGMP - Current Good Manufacturing Practices compliance

- All Product contact parts AISI 316 & non contact parts AISI 304.

- To achieve maximum bulk density and output by various type of rolls

- Available different shape of surface rolls - 1. Plain 2.Corrugated 3. Knurled.

- Heavy duty model with horizontal feeding system.

- Roller Drive vertical movement with hydraulic pressure.

- Bigger Roller size with Dia 300 x Width 330 mm.

- 4 Nos. feed screw with Vertical drive & Vacuumized feeder chamber.

- Uniform force distribution system with hydraulically operated to be provided for produce granules equal quality

- A C Frequency Variable Speed Drive for feed screw

- Top and bottom scrapper of the roll to scrape off powder sticking on the roll.

- Enclosed drive with heavy duty gear box and motor for roll and auger/feeder.

- The auger/ feeder assembly designed with easily attached and disassembled with roller assembly for cleaning & dismantling.

Optional Features :

- Inline Granulation with Granulator & sifting

- PLC Controls with HMI touch screen.

- Automatic loading by Vacuum Transfer system.

- Flame Proof Electrical

- AC frequency drive for Roller.

Safety Features:

- Limit switch for chamber, Slip clutch at drive of auger

- Overload relay & Emergency stop.

Optional Features:

- PLC Controls with HMI touch screen.

- Inline Granulation with Granulator, sifting and Vacuum Transfer system.

- Flame Proof Electrical.

- AC frequency drive for Roller

|

Free flowing granules for Automatic packing

Free flowing granules for Automatic packing