|

Application & Process :

Oscillating granulator is used for gentle homogenization, size reduction, grading and sieving of dry, sensitive powders and granules in pharmaceutical, chemical and food industries.

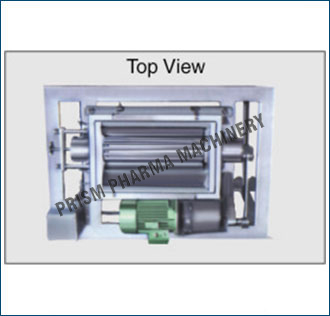

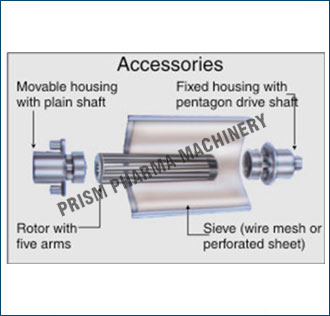

Oscillating Granulator has one rotor with five edges, which oscillate on horizontal axis at about 180 per minutes. There is one half round sieve mounted at the bottom of the rotor. Product is charged from the top through in feed hopper and material falls on the rotor lades. The particles are broken by a set of oscillating bars arranged in cylindrical form over a screen of suitable mesh. Due to the sharp edges on rotor, the downsizing of particle takes place and through sieve material gets pushed outward from the bottom opening.

Salient Features: :

- Design is cGMP - Current Good Manufacturing Practices compliance.

- All Product contact parts AISI 316 & non contact parts AISI 304.

- Uniformly granulation & fewer fines of wet material and dry materials.

- Rotor move oscillating motion with 180 stroke per minute.

- Easy to operate; move, clean, convenient

- An Inline granulation & user friendly.

- Zero dusting & maintenance free.

Optional Features :

- Flame proof motor and Push Button Station.

- Inline granulation with Roll compactor & Tipper with FBD Bowl.

Safety Features :

- Limit switch at charging hopper & over load relay protection.

|